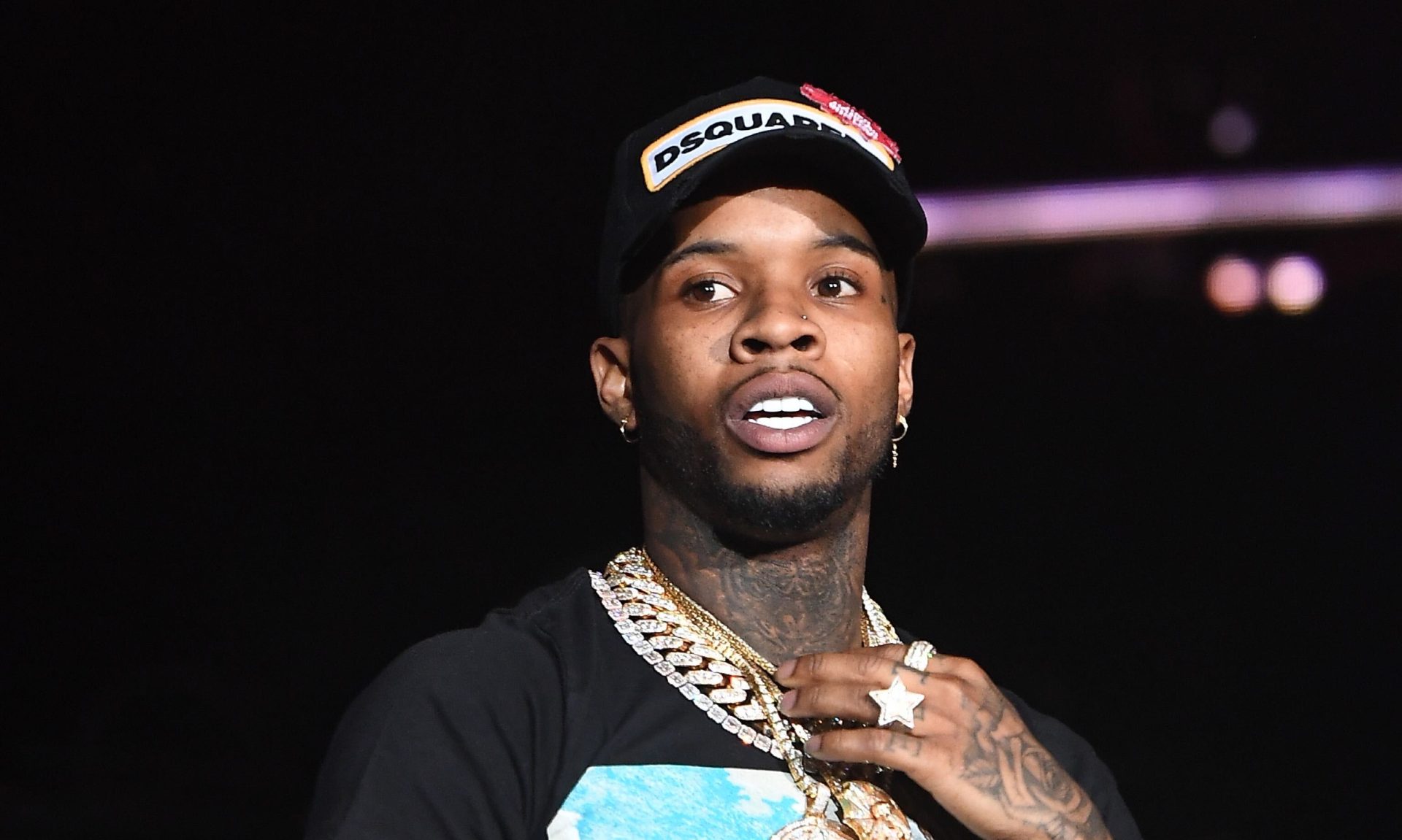

graphic: Researchers from MIT and elsewhere have established a framework that could enable a robotic to effectively complete complex manipulation responsibilities with deformable objects, like dough or fabric, that demand many resources and just take a long time to complete.

look at more

Credit history: Impression courtesy of Yunzhu Li, Chuang Gan, et al.

Picture a pizza maker doing the job with a ball of dough. She may well use a spatula to elevate the dough on to a chopping board then use a rolling pin to flatten it into a circle. Straightforward, appropriate? Not if this pizza maker is a robot.

For a robotic, operating with a deformable item like dough is difficult mainly because the condition of dough can change in several means, which are difficult to signify with an equation. Plus, making a new form out of that dough demands various steps and the use of unique tools. It is specifically difficult for a robot to discover a manipulation undertaking with a extended sequence of techniques — exactly where there are many feasible choices — considering that discovering typically happens by means of trial and error.

Scientists at MIT, Carnegie Mellon University, and the University of California at San Diego, have appear up with a better way. They made a framework for a robotic manipulation program that takes advantage of a two-stage mastering system, which could allow a robot to conduct complex dough-manipulation responsibilities above a very long timeframe. A “teacher” algorithm solves each phase the robotic have to take to full the process. Then, it trains a “student” machine-learning product that learns abstract ideas about when and how to execute every single ability it wants through the undertaking, like working with a rolling pin. With this know-how, the process good reasons about how to execute the competencies to total the overall endeavor.

The researchers show that this method, which they get in touch with DiffSkill, can execute complicated manipulation duties in simulations, like cutting and spreading dough, or gathering items of dough from all around a chopping board, while outperforming other equipment-discovering procedures.

Outside of pizza-creating, this strategy could be applied in other configurations where a robot desires to manipulate deformable objects, this kind of as a caregiving robotic that feeds, bathes, or attire someone elderly or with motor impairments.

“This method is nearer to how we as individuals plan our actions. When a human does a extensive-horizon process, we are not writing down all the aspects. We have a increased-stage planner that about tells us what the stages are and some of the intermediate objectives we require to realize along the way, and then we execute them,” states Yunzhu Li, a graduate pupil in the Pc Science and Synthetic Intelligence Laboratory (CSAIL), and author of a paper presenting DiffSkill.

Li’s co-authors consist of lead author Xingyu Lin, a graduate university student at Carnegie Mellon University (CMU) Zhiao Huang, a graduate university student at the University of California at San Diego Joshua B. Tenenbaum, the Paul E. Newton Profession Progress Professor of Cognitive Science and Computation in the Department of Mind and Cognitive Sciences at MIT and a member of CSAIL David Held, an assistant professor at CMU and senior creator Chuang Gan, a study scientist at the MIT-IBM Watson AI Lab. The analysis will be offered at the Intercontinental Convention on Studying Representations.

College student and teacher

The “teacher” in the DiffSkill framework is a trajectory optimization algorithm that can resolve brief-horizon jobs, the place an object’s first point out and target locale are near jointly. The trajectory optimizer is effective in a simulator that styles the physics of the serious world (known as a differentiable physics simulator, which puts the “Diff” in “DiffSkill”). The “teacher” algorithm works by using the info in the simulator to understand how the dough need to move at each stage, 1 at a time, and then outputs all those trajectories.

Then the “student” neural network learns to imitate the steps of the instructor. As inputs, it uses two digital camera pictures, a person showing the dough in its present-day condition and a different showing the dough at the conclude of the process. The neural network generates a high-degree plan to determine how to website link diverse abilities to attain the objective. It then generates particular, quick-horizon trajectories for each individual skill and sends commands specifically to the tools.

The researchers employed this technique to experiment with three different simulated dough-manipulation duties. In a person undertaking, the robotic employs a spatula to elevate dough onto a slicing board then works by using a rolling pin to flatten it. In yet another, the robot utilizes a gripper to assemble dough from all in excess of the counter, spots it on a spatula, and transfers it to a cutting board. In the 3rd activity, the robotic cuts a pile of dough in half using a knife and then uses a gripper to transport each piece to different places.

A slice above the rest

DiffSkill was capable to outperform well-known approaches that depend on reinforcement learning, in which a robot learns a undertaking as a result of demo and error. In simple fact, DiffSkill was the only technique that was able to efficiently complete all 3 dough manipulation responsibilities. Curiously, the scientists observed that the “student” neural community was even equipped to outperform the “teacher” algorithm, Lin states.

“Our framework supplies a novel way for robots to get new expertise. These techniques can then be chained to remedy much more complicated tasks which are outside of the ability of prior robot units,” claims Lin.

Due to the fact their system focuses on managing the tools (spatula, knife, rolling pin, and so on.) it could be utilized to unique robots, but only if they use the certain tools the scientists described. In the upcoming, they approach to combine the shape of a software into the reasoning of the “student” community so it could be used to other tools.

The researchers intend to strengthen the efficiency of DiffSkill by applying 3D facts as inputs, alternatively of photographs that can be hard to transfer from simulation to the actual world. They also want to make the neural network organizing process far more economical and acquire extra varied schooling information to improve DiffSkill’s capacity to generalize to new cases. In the very long operate, they hope to implement DiffSkill to extra diverse duties, like cloth manipulation.

This get the job done is supported, in element, by the National Science Foundation, LG Electronics, the MIT-IBM Watson AI Lab, the Office environment of Naval Analysis, and the Defense Innovative Study Jobs Company Machine Frequent Feeling system.

###

Written by Adam Zewe, MIT News Office environment

Paper: “DiffSkill: Ability Abstraction from Differentiable Physics for Deformable Item Manipulations with Tools”

https://openreview.net/pdf?id=Kef8cKdHWpP

Article Title

“DiffSkill: Ability Abstraction from Differentiable Physics for Deformable Object Manipulations with Tools”

Disclaimer: AAAS and EurekAlert! are not dependable for the accuracy of news releases posted to EurekAlert! by contributing institutions or for the use of any info as a result of the EurekAlert procedure.